Intelligent Image and Video Analytics

In recent years, image processing has increasingly incorporated machine learning techniques. Deep Convolutional Networks (CNNs) have proven particularly poweful, excelling in the classification and recognition of visual content. One of the first major breakthroughs was the reliable recognition of handwritten postal codes, which marked a milestone in automated text recognition. This was followed by further significant advances, such as in facial recognition, automatic license plate detection, identification of individuals and traffic signs, as well as the detection and spatial localization of obstacles.

Intelligent image and video processing systems are now widely used beyond mobility and security applications. In the food industry, they are used for quality control, in medicine they support the early diagnosis of skin diseases and tumors. In agriculture, they enable the detection of weeds, plant diseases, and pests, contributing to more efficient use of resources. In the context of environmental and climate protection, they are used in wildfire early detection systems to help identify fires more quickly and better protect both people and nature. In the field of recycling, this technology helps to accurately and efficiently identify plastics, making their reuse and recycling more effective.

| Contact |

| Katja Kossira, M.Sc. |

| E-Mail: katja.kossira@fau.de |

| Link to person |

| PD Dr.-Ing. habil. Jürgen Seiler |

| E-Mail: juergen.seiler@fau.de |

| Link to person |

Application of Methods of Intelligent Image and Video Analysis in the Field of Recycling

The increasing relevance of the topic of environmental and climate protection affects many areas of our lives: Beaches on vacation are littered with disposable plastic bottles and there is a huge garbage swirl floating in the ocean. Temperatures are rising, yet you can hardly find anything in the supermarket that isn’t wrapped in plastic. Currently, 67% of this waste is thermally recycled, i.e. incinerated, but the efficiency of this process is merely 30%, while a lot of CO2 is emitted in the process (Source: Plastikatlas 20191). Since recycling is significantly more efficient at 85% and also emits less CO2, it is important to create efficient and inexpensive methods to classify plastics properly so that they can be reused.

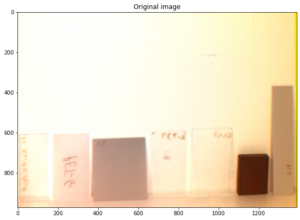

To support this development, a new approach will be explored that uses intelligent image and video analysis with the aid of AI, aiming to decide which type of plastic the sample belongs to. The idea origins in the discovery of carbon chains of plastics reflecting light at different wavelengths in the infrared range to different extents, resulting in various colors for characteristic plastics. This is shown exemplary in the following figure (left: original representation, right: superimposition of images taken with filters of wavelengths 850nm, 1000nm and 1150nm).

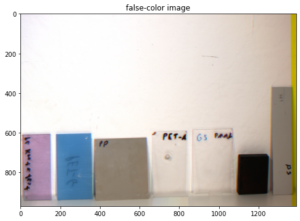

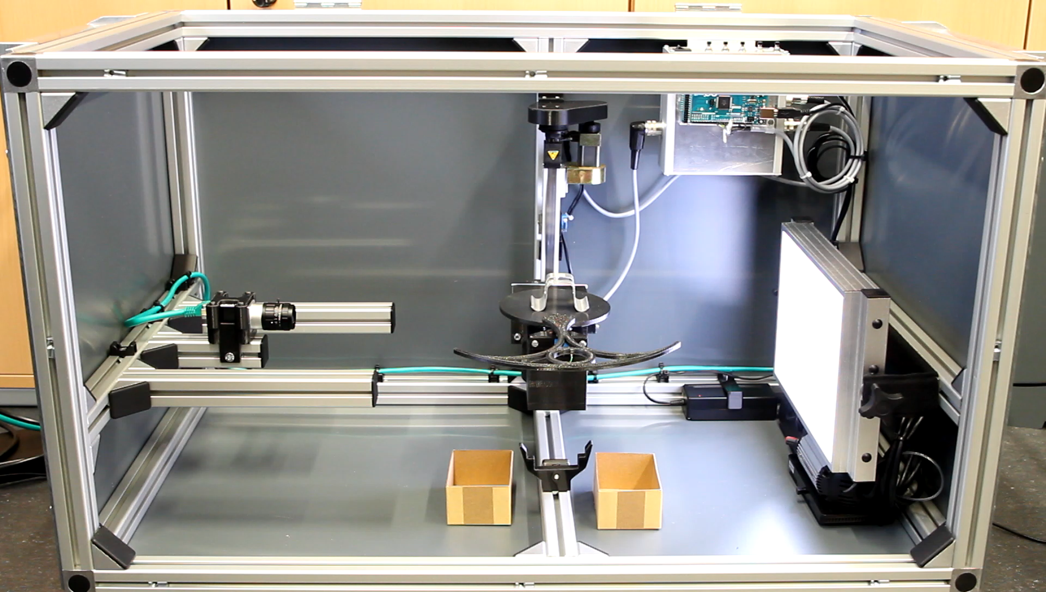

In order to automatically recognize plastics in the future, the camera array for multispectral imaging (CAMSI) will be further developed and adapted to the requirements. The spectral fingerprints of the different plastic classes will be determined and subsequently used to train a model. In addition, a decision matrix is created that determines the optimal filter selection based on significant peaks of the spectra. The output is then used for an unambiguous classification and the recyclable material can be fed into the recycling process. The new method is to be used, for example, in deposit machines or at sorting facilities of recycling centers.

In October 2024, this research was awarded the FAU Sustainability Award (more information).

1 https://www.bund.net/fileadmin/user_upload_bund/publikationen/chemie/chemie_plastikatlas_2019.pdf

Embedded Perception for Autonomous Vehicles

| Contact |

| Maximiliane Gruber, M. Sc. |

| E-Mail: maximiliane.gruber@fau.de |

| Link to person |

| Kamal Nambiar, M. Sc. |

| E-Mail: kamal.nambiar@fau.de |

| Link to person |

| PD Dr.-Ing. habil. Jürgen Seiler |

| E-Mail: juergen.seiler@fau.de |

| Link to person |

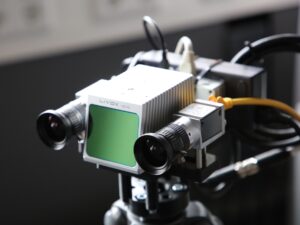

The primary goal of Embedded Perception is to develop a data-driven framework that enables object recognition in road data, thereby facilitating the advancement of autonomous driving vehicles. The hardware system comprises multiple cameras and LiDAR sensors, while the software system consists of both an offline and an online perception component. The online component is designed to deliver real-time and precise results, effectively utilizing the limited computing resources onboard. On the other hand, the offline component operates independently on the same data once the recordings are complete, benefiting from more extensive compute resources and enabling the execution of highly complex algorithms. As a result, the outcomes are expected to be more dependable. Such a system can be utilized to generate extensive reference datasets encompassing diverse traffic and weather conditions.

The development of the Embedded Perception Framework poses several signal processing challenges, including sensor calibration, data compression, multi-modal data analysis and fusion, data augmentation, and the development of perception algorithms, among others. The key areas of our research can be broadly divided into:

- LiDAR-Camera Self-Calibration To address the requirements of a diverse operating domain and avoid heuristically tuned algorithms, we propose a self-calibration pipeline based on deep learning. This pipeline aims to perform simultaneous intrinsic calibration of the camera sensor and extrinsic calibration of the LiDAR camera setup.

- LiDAR Point Cloud Compression Efficient compression algorithms are crucial for handling the substantial data produced by LiDAR sensors, during storage and transmission. Apart from reducing memory and storage costs, smaller file sizes facilitate faster information exchange between autonomous vehicles, thereby decreasing the overall latency of the perception system. Given that these signals primarily serve downstream perception tasks like object detection, our research goes beyond traditional quality metrics like PSNR, and we develop compression algorithms that also consider their impact on detection accuracy in state-of-the-art perception algorithms.

|

Fig. 1: Demonstrator setup consisting of stereo camera and LiDAR sensor.

|

Fig. 2: Performance improvement by our methods for learning image distortions in JPEG2000 coded images.

|

|

|

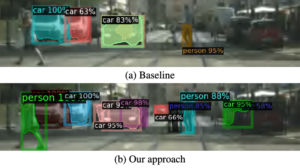

- Learning Image Distortions for Domain Adaptation Since data-driven methods learn a particular task from annotated data samples, such methods heavily depend on the quality of the training data. That is, the training data must sufficiently resemble the data encountered during application and testing. In practice, however, unknown distortion can lead to a domain gap between training and test data, impeding the performance of a machine vision system. Examples of such unknown distortions that occur in image data are blur, noise, and coding. These distortions differ for example for different camera systems. Fig. 2a illustrates an example of the drop in performance for JPEG2000-encoded test data if the training data did not contain such distortions. To address the performance drop of image processing systems in such cases, we explore methods for learning the above mentioned unknown image distortions. The learned image distortions are then emulated on clean data, which serve as additional training data to improve the performance of image processing systems. In our work, we consider machine vision systems as a black box and develop general methods that can be used for various tasks. This approach is also called pixel-level domain adaptation. Fig. 2b shows the improvement in object detection, when using our method.

- Road Lane Detection Road Lane detection is a critical component for ensuring the safe navigation of autonomous vehicles. Our research focuses on developing a neural network-based model that leverages fused features from LiDAR and monocular camera signals to generate a 3D profile of the road. The lane detection capabilities of our model exhibit robustness to road slopes and provide accurate depth estimation.

- Object Detection and Object Tracking Object detection involves identifying and localizing road users and road signs within a captured frame from the vehicle’s sensors. Object tracking enhances perception by associating identical objects across frames, enabling motion estimation for dynamic entities like pedestrians and vehicles. In the task of 3D multi-object tracking, two approaches are commonly used. The first approach employs an end-to-end trainable object tracking system for a sequence of frames. The second approach involves using a 3D object detector for each frame individually, followed by association using a Kalman filter and the Hungarian algorithm. Our research investigates both approaches and further optimizes them to address the challenges of speed and accuracy in our online and offline processing pipelines.

| Contact |

| PD Dr.-Ing. habil. Jürgen Seiler |

| E-Mail: juergen.seiler@fau.de |

| Link to Person |

Artificial intelligence for quality assurance in industrial manufacturing

The growing amount of automation influences every aspect of our daily live. A topic that is very strongly affected by this transformation is industrial manufacturing. Modern production lines already run nearly without any human action. Due to the upcoming changes that come with Industry 4.0 this phenomenon will be even more reinforced. In order to guarantee the quality of the items produced in that manner, a final visual quality control has to be conducted. Up to now, this is still often done manually. As this is a tiring, monotonous and exhausting labour, automated solutions are searched for this problem as well.

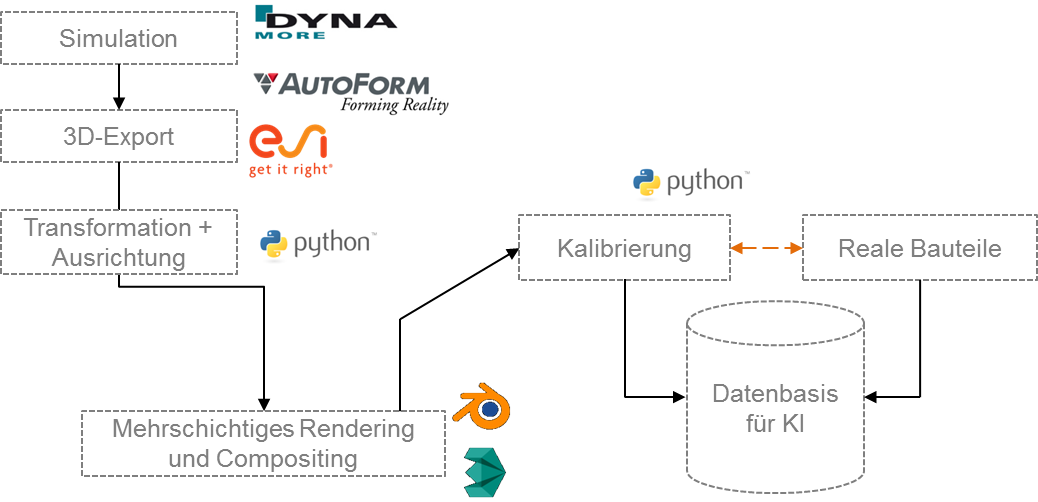

Since some years, there are several automated optical inspection systems. Up to now, those systems use classical image processing techniques. Those techniques require a strict calibration and adjustment of the tolerance ranges and test criteria for the current item before the inspection can start. Especially in the context of Industry 4.0 with often changing inspection tasks and small batch series this is becoming very inefficient. As an alternative, a new approach is developed that uses Machine Learning techniques to assess whether an item is erroneous or not. The traditional approach to solve this problem is to acquire a huge amount to images of erroneous and fault-less items in order to use these images for the training of a neural network. The problem with this approach is that first of all a sufficiently large number of items has to be produced to acquire images of them. Another restriction is that enough erroneous items have to be available to guarantee a reliable training.

Especially in terms of a fast adaption of the production and the fabrication of individual items, this approach is not suited well. In order to eliminate the production and following assessment of items for the generation of training data for the neural network another approach is followed here. Here the training data is not acquired by a camera, but generated by a model. Therefore, images of the item that will be produced are generated based on a model of this item. The neural network is trained on these model-generated images and afterwards applied to the real acquired images of the item that is to be inspected. By this a separation into good and erroneous items can be performed.

2024

- , , , :

Conditional Optimal Filter Selection for Multispectral Object Classification

International Conference on Image Processing (ICIP) (Abu Dhabi, 27. October 2024 - 30. October 2024)

DOI: 10.1109/ICIP51287.2024.10647688

URL: https://arxiv.org/abs/2410.02001

BibTeX: Download - , , :

Inter-Camera Color Correction for Multispectral Imaging with Camera Arrays Using a Consensus Image

International Workshop on Multimedia Signal Processing (MMSP) (West Lafayette, 2. October 2024 - 4. October 2024)

DOI: 10.1109/MMSP61759.2024.10743810

URL: https://arxiv.org/abs/2410.23043

BibTeX: Download

2022

- , , , , :

Domain Adaptation for Unknown Image Distortions in Instance Segmentation

IEEE International Conference on Image Processing (ICIP) (Bordeaux, 16. October 2022 - 19. October 2022)

DOI: 10.1109/ICIP46576.2022.9897339

URL: https://arxiv.org/abs/2210.02386

BibTeX: Download - , , :

Increasing the Accuracy of a Neural Network Using Frequency Selective Mesh-to-Grid Resampling

IEEE International Symposium on Circuits and Systems (ISCAS) (, 28. May 2022 - 1. June 2022)

DOI: 10.1109/iscas48785.2022.9937735

URL: https://arxiv.org/abs/2209.14431

BibTeX: Download

2021

- , , , :

Component-Wise Power Estimation of Electrical Devices Using Thermal Imaging

In: IEEE Transactions on Consumer Electronics 67 (2021), p. 383-392

ISSN: 0098-3063

DOI: 10.1109/TCE.2021.3122076

URL: http://arxiv.org/abs/2307.08354

BibTeX: Download - , , , , , :

3D Rendering Framework for Data Augmentation in Optical Character Recognition

2021 International Symposium on Signals, Circuits and Systems (ISSCS) (Iasi, Romania (virtual), 15. July 2021 - 16. July 2021)

In: ISSCS 2021 - International Symposium on Signals, Circuits and Systems 2021

DOI: 10.1109/ISSCS52333.2021.9497438

URL: https://arxiv.org/abs/2209.14970

BibTeX: Download

2020

- , , , , , :

Quality Assurance of Weld Seams Using Laser Triangulation Imaging and Deep Neural Networks

IEEE International Workshop on Metrology for Industry 4.0 and IoT (Rome (Virtual Conference), Italy, 3. June 2020 - 5. June 2020)

In: 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT 2020

DOI: 10.1109/MetroInd4.0IoT48571.2020.9138205

BibTeX: Download

2019

- , , , :

Deep Counting Model Extensions with Segmentation for Person Detection

44th IEEE International Conference on Acoustics, Speech, and Signal Processing, ICASSP 2019 (Brighton, 12. May 2019 - 17. May 2019)

In: ICASSP, IEEE International Conference on Acoustics, Speech and Signal Processing - Proceedings 2019

DOI: 10.1109/ICASSP.2019.8682662

BibTeX: Download - , , , , :

Deep Network Pruning for Object Detection

26th IEEE International Conference on Image Processing, ICIP 2019 (Taipei, 22. September 2019 - 25. September 2019)

In: Proceedings - International Conference on Image Processing, ICIP 2019

DOI: 10.1109/ICIP.2019.8803505

BibTeX: Download - , , , , :

Irregular Motion Detection in Automotive Navigation Systems with Soft Map Rotation

Proceedings of the 37th IEEE International Conference On Consumer Electronics ICCE (Las Vegas, NV, 11. January 2019 - 13. January 2019)

In: Proceedings of the 37th IEEE International Conference On Consumer Electronics ICCE 2019

DOI: 10.1109/icce.2019.8661963

BibTeX: Download

2018

- , , , , :

Robustness of Deep Convolutional Neural Networks for Image Degradations

IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP) (Calgary, Canada, 15. April 2018 - 20. April 2018)

DOI: 10.1109/icassp.2018.8461907

BibTeX: Download

2017

- , , , :

Reliable Pedestrian Detection Using A Deep Neural Network Trained On Pedestrian Counts

IEEE International Conference on Image Processing (ICIP) (Beijing, 17. September 2017 - 20. September 2017)

DOI: 10.1109/ICIP.2017.8296368

BibTeX: Download - , , , :

Detecting Closely Spaced and Occluded Pedestrians Using Specialized Deep Models for Counting

IEEE Visual Communications and Image Processing (VCIP) (St. Petersburg, Florida, 10. December 2017 - 13. December 2017)

DOI: 10.1109/VCIP.2017.8305064

BibTeX: Download - , , , :

Pedestrian Counting Using Deep Models Trained on Synthetically Generated Images

International Conference on Computer Vision Theory and Applications (VISAPP) (Porto, Portugal, 27. February 2017 - 1. March 2017)

DOI: 10.5220/0006132600860097

BibTeX: Download - , , , , :

Finger-Trace Generator for SWYPE Touch Screen Testing Applications

7th IEEE International Conference On Consumer Electronics ICCE (Berlin, 3. September 2017 - 6. September 2017)

DOI: 10.1109/ICCE-Berlin.2017.8210606

BibTeX: Download

2016

- , , , :

Moving Object Detection in the H.264/AVC Compressed Domain

In: APSIPA Transactions on Signal and Information Processing 5 (2016), p. 1-20

ISSN: 2048-7703

DOI: 10.1017/ATSIP.2016.18

BibTeX: Download - , , , , :

Identification of Irregular Motion in Automotive Navigation Systems Using Novelty Detection

IEEE Symposium Series on Computational Intelligence SSCI (Athens, 6. December 2016 - 9. December 2016)

DOI: 10.1109/SSCI.2016.7850000

BibTeX: Download

2015

- , , , :

Compressed domain moving object detection by spatio-temporal analysis of H.264/AVC syntax elements

31st Picture Coding Symposium, PCS 2015 - with 2015 Packet Video Workshop, PV 2015 (Cairns, 31. May 2015 - 3. June 2015)

DOI: 10.1109/PCS.2015.7170091

BibTeX: Download - , , , , :

Hybrid person detection and tracking in H.264/AVC video streams

10th International Conference on Computer Vision Theory and Applications, VISAPP 2015 (Berlin, 11. March 2015 - 14. March 2015)

DOI: 10.5220/0005296704780485

BibTeX: Download

2014

- , , , , :

Real-time motion classification of HD video sequences on embedded systems

6th European Embedded Design in Education and Research Conference, EDERC 2014 (Milano, 11. September 2014 - 12. September 2014)

DOI: 10.1109/EDERC.2014.6924379

BibTeX: Download

2013

- , , , :

Compressed domain moving object detection based on H.264/AVC macroblock types

8th International Conference on Computer Vision Theory and Applications, VISAPP 2013 (Barcelona, 21. February 2013 - 24. February 2013)

DOI: 10.5220/0004296602190228

BibTeX: Download - , , :

BM3D-verfeinerte Zwischenbildsynthese für unterschiedlich aufgelöste Referenzansichten

15. ITG-Fachtagung für Elektronische Medien (Dortmund, 26. February 2013 - 27. February 2013)

In: 15. ITG-Fachtagung für Elektronische Medien, Dortmund, Deutschland: 2013

DOI: 10.17877/DE290R-5368

BibTeX: Download - , , , , :

A novel similarity-invariant line descriptor for geometric map registration

2013 20th IEEE International Conference on Image Processing, ICIP 2013 (Melbourne, VIC, 15. September 2013 - 18. September 2013)

DOI: 10.1109/ICIP.2013.6738621

BibTeX: Download - , :

Comparative image quality assessment using free energy minimization

2013 38th IEEE International Conference on Acoustics, Speech, and Signal Processing, ICASSP 2013 (Vancouver, BC, 26. May 2013 - 31. May 2013)

DOI: 10.1109/ICASSP.2013.6637980

BibTeX: Download - , , , :

A dual-model approach to blind quality assessment of noisy images

2013 Picture Coding Symposium, PCS 2013 (San Jose, CA, 8. December 2013 - 11. December 2013)

DOI: 10.1109/PCS.2013.6737675

BibTeX: Download - , , , :

Retina model inspired image quality assessment

2013 IEEE International Conference on Visual Communications and Image Processing, IEEE VCIP 2013 (Kuching, Sarawak, 17. November 2013 - 20. November 2013)

DOI: 10.1109/VCIP.2013.6706367

BibTeX: Download

2012

- , :

Shape Adaptive Mean Shift Object Tracking Using Gaussian Mixture Models

In: N. Adami, A. Cavallaro, R. Leonardi, P. Migliorati (ed.): Analysis, Retrieval and Delivery of Multimedia Content, New York, NY: Springer, 2012, p. 107-122 (Lecture Notes in Electrical Engineering, Vol.158)

ISBN: 978-1-4614-3831-1

DOI: 10.1007/978-1-4614-3831-1_7

BibTeX: Download - , , , , :

Blind frame freeze detection in coded videos

29th Picture Coding Symposium, PCS 2012 (Krakow, 7. May 2012 - 9. May 2012)

DOI: 10.1109/PCS.2012.6213315

BibTeX: Download - , , , , :

Freeze detection in 2D navigation video sequences by matching of extracted line segments

2012 IEEE International Conference on Vehicular Electronics and Safety, ICVES 2012 (Istanbul, 24. July 2012 - 27. July 2012)

DOI: 10.1109/ICVES.2012.6294329

BibTeX: Download

2011

- , , , :

A compressed domain change detection algorithm for RTP streams in video surveillance applications

3rd IEEE International Workshop on Multimedia Signal Processing, MMSP 2011 (Hangzhou, 17. October 2011 - 19. October 2011)

DOI: 10.1109/MMSP.2011.6093838

BibTeX: Download - , :

AUTO GMM-SAMT: An automatic object tracking system for video surveillance in traffic scenarios

In: Eurasip Journal on Image and Video Processing 2011 (2011), p. 14

ISSN: 1687-5176

DOI: 10.1155/2011/814285

BibTeX: Download - , , :

Mean shift object tracking using a 4d kernel and linear prediction

International Conference on Computer Vision Theory and Application, VISAPP 2011 (Vilamoura, Algarve, 5. March 2011 - 7. March 2011)

DOI: 10.5220/0003327305880593

BibTeX: Download - , , , :

Boosting based object detection using a geometric model

2011 18th IEEE International Conference on Image Processing, ICIP 2011 (Brussels, 11. September 2011 - 14. September 2011)

DOI: 10.1109/ICIP.2011.6116487

BibTeX: Download - , , , :

Introduction to the issue on recent advances in video processing for consumer displays

In: IEEE Journal of Selected Topics in Signal Processing 5 (2011), p. 213-216

ISSN: 1932-4553

DOI: 10.1109/JSTSP.2011.2109130

BibTeX: Download

2010

- , :

Shape Adaptive Mean Shift Object Tracking Using Gaussian Mixture Models

11th IEEE International Workshop on Image Analysis for Multimedia Interactive Services (WIAMIS) (Desenzano del Garda, 12. April 2010 - 14. April 2010)

URL: https://ieeexplore.ieee.org/document/5617670

BibTeX: Download - , , :

Real-time moving object detection in video sequences using spatio-temporal adaptive Gaussian mixture models

5th International Conference on Computer Vision Theory and Applications, VISAPP 2010 (Angers, 17. May 2010 - 21. May 2010)

URL: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=77956329028∨igin=inward

BibTeX: Download - , , :

Blind GOP structure analysis of MPEG-2 and H.264/AVC decoded video

28th Picture Coding Symposium, PCS 2010 (Nagoya, 8. December 2010 - 10. December 2010)

DOI: 10.1109/PCS.2010.5702480

BibTeX: Download - , , :

A no-reference blocking artifacts visibility estimator in images

2010 17th IEEE International Conference on Image Processing, ICIP 2010 (Hong Kong, 26. September 2010 - 29. September 2010)

DOI: 10.1109/ICIP.2010.5652927

BibTeX: Download

2009

- , , , , :

Temporal trajectory aware video quality measure

In: IEEE Journal of Selected Topics in Signal Processing 3 (2009), p. 266-279

ISSN: 1932-4553

DOI: 10.1109/JSTSP.2009.2015375

BibTeX: Download - , :

Scale and shape adaptive mean shift object tracking in video sequences

17th European Signal Processing Conference, EUSIPCO 2009 (Glasgow, 24. August 2009 - 28. August 2009)

DOI: 10.5281/zenodo.41559

BibTeX: Download

2008

- , , , , , , :

Low-Complexity Heterogeneous Video Transactions using Data Mining

In: IEEE Transactions on Multimedia 10 (2008), p. 286-299

ISSN: 1520-9210

DOI: 10.1109/TMM.2007.911838

BibTeX: Download

2007

- , , , :

Temporal registration using 3D phase correlation and a maximum likelihood approach in the perceptual evaluation of video quality

2007 IEEE 9Th International Workshop on Multimedia Signal Processing, MMSP 2007 (Chania, Crete, 1. October 2007 - 3. October 2007)

DOI: 10.1109/MMSP.2007.4412851

BibTeX: Download - , , , , :

Perceptually motivated spatial and temporal integration of pixel based video quality measures

Mobile Content Quality of Experience, MobConQoE '07 (Vancouver, BC, 14. August 2007 - 17. August 2007)

DOI: 10.1145/1577504.1577508

BibTeX: Download

2006

- , , , :

Comparison of Matching Strategies for Temporal Frame Registration in the Perceptual Evaluation of Video Quality

2nd International Workshop on Video Processing and Quality Metrics for Consumer Electronics (Scottsdale, Arizona, 22. January 2006 - 24. January 2006)

BibTeX: Download - , , , :

Influence of the presentation time on subjective votings of coded still images

2006 IEEE International Conference on Image Processing, ICIP 2006 (Atlanta, GA, 8. October 2006 - 11. October 2006)

DOI: 10.1109/ICIP.2006.312449

BibTeX: Download

2005

- , , :

Subjektiver Videobetrachtungstest für niederratige Multimedia-Szenarien

Elektronische Medien: 11. Dortmunder Fernsehseminar, ITG-Fachbericht, (, 9. September 2005 - 10. September 2005)

BibTeX: Download - , , , :

Model based segmentation of motion fields in compressed video sequences using partition projection and relaxation

Visual Communications and Image Processing 2005 (Beijing)

DOI: 10.1117/12.631458

BibTeX: Download - , , , :

Stochastic Motion Coherency Analysis for Motion Vector Field Segmentation on Compressed Video Sequences

6th Workshop on Image Analysis for Multimedia Interactive Services (WIAMIS), Montreux, Switzerland (, 13. April 2005 - 15. April 2005)

BibTeX: Download - , , , :

Bayesian method for motion segmentation and tracking in compressed videos

In: Computer Science 3663 (2005), p. 277-284

ISSN: 1508-2806

DOI: 10.1007/11550518_35

BibTeX: Download - , , , , :

Additive non-Gaussian noise attacks on the scalar Costa scheme (SCS)

Proceedings of SPIE-IS and T Electronic Imaging - Security, Steganography, and Watermarking of Multimedia Contents VII (San Jose, CA, 17. January 2005 - 20. January 2005)

In: Delp III E.J.; Wong P.W. (ed.): Proceedings of SPIE-IS and T Electronic Imaging - Security, Steganography, and Watermarking of Multimedia Contents VII 2005

DOI: 10.1117/12.587492

BibTeX: Download

2004

- , , , , :

Temporal video segmentation using global motion estimation and discrete curve evolution

2004 International Conference on Image Processing, ICIP 2004 (Singapore, 24. October 2004 - 27. October 2004)

DOI: 10.1109/ICIP.2004.1418771

BibTeX: Download

2003

- , , , :

Optimality of SCS Watermarking

Security and Watermarking of Multimedia Contents V (Santa Clara, CA)

DOI: 10.1117/12.477329

BibTeX: Download - , , , :

Steganographic System Based on Higher-Order Statistics

Security and Watermarking of Multimedia Contents V (Santa Clara, CA)

DOI: 10.1117/12.477301

BibTeX: Download

2002

- , , , :

Video analysis for universal multimedia messaging

5th IEEE Southwest Symposium on Image Analysis and Interpretation, SSIAI 2002 (Santa Fe, 7. April 2002 - 9. April 2002)

DOI: 10.1109/IAI.2002.999920

BibTeX: Download - , , , :

Automatic video structuring for multimedia messaging

11th European Signal Processing Conference, EUSIPCO 2002 (Toulouse, 3. September 2002 - 6. September 2002)

URL: https://www.scopus.com/inward/record.uri?partnerID=HzOxMe3b&scp=84960886243&origin=inward

BibTeX: Download

2000

- , , :

Adaptive Multimedia Messaging Based on MPEG-7 - The M3-Box

Second International Symposium on Mobile Multimedia Systems and Applications (Delft, 9. November 2000 - 10. November 2000)

BibTeX: Download - , :

Visual Feature Discrimination versus Compression Ratio for Polygonal Shape Descriptors

Internet Multimedia Management Systems, SPIE (Boston, Mass., 6. November 2000 - 7. November 2000)

BibTeX: Download - , :

Polygonal Shape Descriptors - An Efficient Solution for Image Retrieval and Object Localization

34th Asilomar Conference on Signals, Systems, and Computers (Pacific Grove, 29. October 2000 - 1. November 2000)

BibTeX: Download - , :

Plug and Play for Mobile Users

In: Siemens CIO Journal, 2000, p. 11-12

BibTeX: Download

1999

- , :

Fast Estimation of an Expressive Global Motion Description in Block Coded Sequences

Workshop on Image Analysis for Multimedia Interactive Services (Berlin, 31. May 1999 - 1. June 1999)

BibTeX: Download - , :

Global Motion Estimation in Image Sequences Using Robust Motion Vector Field Segmentation

ACM Multimedia 99 (Orlando, Florida, 30. October 1999 - 5. November 1999)

BibTeX: Download

1998

- , , :

Schnelle Bestimmung von Kamerabewegungen in blockbasiert codierten Videosequenzen

In: Proceedings 20. DAGM-Symposium Mustererkennung 1998

BibTeX: Download

1995

- , :

Bayesian Algorithms for Adaptive Change Detection in Image Sequences Using Markov Random Fields

In: Signal Processing-Image Communication 7 (1995), p. 147-160

ISSN: 0923-5965

BibTeX: Download - , , :

On Texture Analysis: Local Energy Transforms Versus Quadrature Filters

In: Signal Processing 45 (1995), p. 173-181

ISSN: 0165-1684

BibTeX: Download - :

Modelle zur regionenorientierten Bildbeschreibung (Dissertation, 1995)

BibTeX: Download

1994

- , :

Disparity-based Segmentation of Stereoscopic foreground/background Image Sequences

In: IEEE Transactions on Communications 42 (1994), p. 673-679

ISSN: 0090-6778

BibTeX: Download - , :

Stochastic Model-Based Image Segmentation Using Functional Approximation

In: IEICE Transactions on Fundamentals of Electronics Communications and Computer Sciences E77-A (1994), p. 1451-1456

ISSN: 0916-8508

BibTeX: Download - , :

Segment-Oriented Coding of Texture Images Based on Successive Approximation

IEEE International Symposium on Speech, Image Processing and Neural Networks, Hong Kong (, 13. April 1994 - 16. April 1994)

BibTeX: Download - , :

A Stochastic Model for Image Segmentation Involving Constrained Least Squares Estimation

IEEE International Symposium on Information Theory, Trondheim (, 27. June 1994 - 1. July 1994)

BibTeX: Download - , :

Ein Modell zur Kompensation örtlicher Wahrnehmungslücken beim menschlichen Sehen basierend auf Lokaler Spektralanalyse

Mustererkennung 1994, Wien (, 21. September 1994 - 23. September 1994)

BibTeX: Download

1993

- , , :

Statistical Model-Based Change Detection in Moving Video

In: Signal Processing 31 (1993), p. 165-180

ISSN: 0165-1684

DOI: 10.1016/0165-1684(93)90063-G

BibTeX: Download - , , :

Change Detection in Image Sequences Using Gibbs Random Fields: A Bayesian Approach

IEEE International Workshop on Intelligent Signal Processing and Communication Systems, Sendai (, 27. October 1993 - 29. October 1993)

BibTeX: Download - , :

Modelling the Visual Process of filling in Based on Localised Spectral Image Analysis

Sixteenth European Conference on Visual Perception, Edinburgh, United Kingdom (, 25. August 1993 - 29. August 1993)

BibTeX: Download - , :

Stochastic Model-Based Image Segmentation Using Functional Approximation

IEEE International Workshop on Intelligent Signal Processing and Communication Systems, Sendai (, 27. October 1993 - 29. October 1993)

BibTeX: Download

1992

- , :

Estimation of Physical Disparity Fields and their Discontinuities for Stereoscopic Images

European Workshop on 3D-TV Signal Processing: From Capture to Display, Rennes (, 9. November 1992 - 10. November 1992)

BibTeX: Download - , :

MAP-Estimation of Dense Disparity-Fields for Stereoscopic Images

2nd Singapore Intern. Conf. on Image Processing, Singapore (, 7. September 1992 - 11. September 1992)

BibTeX: Download - , :

Ein approximationstheoretischer Ansatz zur effizienten Texturanalyse

Mustererkennung 1992, Serie Informatik Aktuell, Berlin, Springer Verlag (, 14. September 1992 - 16. September 1992)

BibTeX: Download - , :

A New Approach Towards Description of Arbitrarily Shaped Image Segments

IEEE International Workshop on Intelligent Signal Processing and Communication Systems, Taipei (, 19. March 1992 - 21. March 1992)

BibTeX: Download

1991

- , :

Partitioning of Stereoscopic Sequences by Evaluation of Stereo Disparity and Temporal Change Detection

Picture Coding Symposium, Tokyo (, 2. September 1991 - 4. September 1991)

BibTeX: Download - , , :

A Statistical Framework for Change Detection in Image Sequences

13ieme Colloque sur le Traitement du Signal et des Images, Juan-Les-Pins (, 16. September 1991 - 20. September 1991)

BibTeX: Download

1990

- , :

Disparity-Based Segmentation of Stereoscopic Images

2nd Workshop on Stereoscopic Television, Darmstadt (, 27. September 1990 - 28. September 1990)

BibTeX: Download - , , :

Combined Displacement Estimation and Segmentation of Stereo Image Pairs based on Gibbs Random Fields

IEEE International Conference on Acoustics, Speech, and Signal Processing, Albuquerque (, 3. April 1990 - 6. April 1990)

BibTeX: Download